| Effective Fabrics Width | 1000~1700mm/Customized |

| Roller Width | 1800mm/Customized |

| Production speed: | 0~30 m/min |

| Demension (L*W*H): | 15950×2100×3600 mm |

| Gross Power | About 105KW |

| Voltage | 380V 50HZ 3Phase / customizable |

| Weight | About 11340KG |

| 1、 | Button type control used; |

| 2、 | the operation is simple; |

| 3、 | take the circulating air drying system; |

| 4、 | electric heating tube heating, temperature controllable; |

| 5、 | constant tension and retractable volume; |

| 6、 | the glue method is simple; |

| 7、 | the machine is humanized design, saving operators; |

| 8、 | The finished material is transported directly to the inspection office |

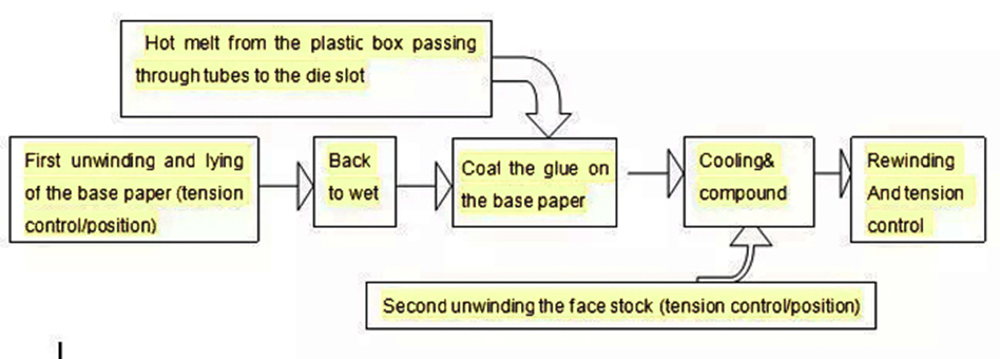

DM-H1800-D1573 equipment control, user-friendly operation, easy maintenance, constant tension, high-precision micro-correction and discharge device, convenient control of the stability of the composite process, the use of circulating wind power heating 12 m oven, constant tension control retractable volume, Cooperate with the finished product to deliver the product. Mechanical specifications: Mechanical spokes 1800mm, production line speed: 3~20M/min. Power supply requirements: Three-phase 380V, air pressure source: 5KG/cm2, 200L/min.

DM-H1800-D1573 equipment control, user-friendly operation, easy maintenance, constant tension, high-precision micro-correction and discharge device, convenient control of the stability of the composite process, the use of circulating wind power heating 12 m oven, constant tension control retractable volume, Cooperate with the finished product to deliver the product. Mechanical specifications: Mechanical spokes 1800mm, production line speed: 3~20M/min. Power supply requirements: Three-phase 380V, air pressure source: 5KG/cm2, 200L/min.